Contents

1 min read

About: Product video about a filter for recycling plastic products. The peculiarity is that transparent granules are obtained from all types of plastic after processing!

Video details & Credits:

- Duration: main 90 seconds

- Format: 2d graphics

- Type: Animated Explainer Video

- Client: DrM (Switzerland)

- Production: Darvideo Animation Studio | darvideo.tv

- Timing: 6 weeks

Story: Plastics find boundless applications in consumer products and garments, come in a huge variety of fibers, shapes and colors and demand various polymers to be applied during the production. Unfortunately, recycling of such mix of plastics requires complex processes and often and up with dark colored polymer pellets which can only be applied for inferior products.

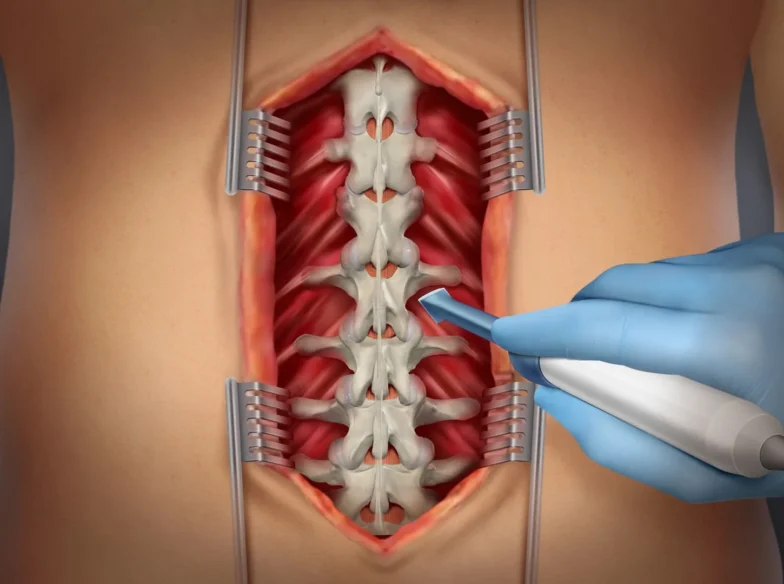

The key to successful recycling of plastics into widely re-usable polymers is purification, which could be done in two ways: depolymerization of the plastic or its solvent dissolution. Both methods pose significant challenges to the equipment, demanding temperatures between 100 and 300 C and pressures up to 100 bar. Moreover, impurities are often micron-sized which require additional separation equipment.

The FUNDABAC® candle filter, with its robust mechanical construction, can be applied as high temperature and high-pressure equipment. Integrated media cleaning, solvent extraction, cake washing, and drying significantly simplify the purification process! The newly developed high-temperature filter media significantly extend their application range and resistance against all kinds of solvents up to 300ºC. It is suited for purification of polymers in plastics recycling, providing clean virgin polymers, assuring its unlimited reusability.

The FUNDABAC® filtration equipment ensures proper and efficient processing, which is key in a new era of plastics recycling!